Here is an introduction to the 3D Shape Classification technology that we have developed as a world pioneer in 3D Artificial Intellegent.

3D shape classification refers to the process of classifying input 3D shapes into predefined classes, and we are the pioneer in the world in developing a 3D AI model that performs 3D shape classification.

For example, consider classifying bolts and screws that are always included in a product.

Although it can be classified by the entire shape of the bolt, it is also possible to classify only by the bolt head because the characteristic of the bolt is the shape of the bolt head.

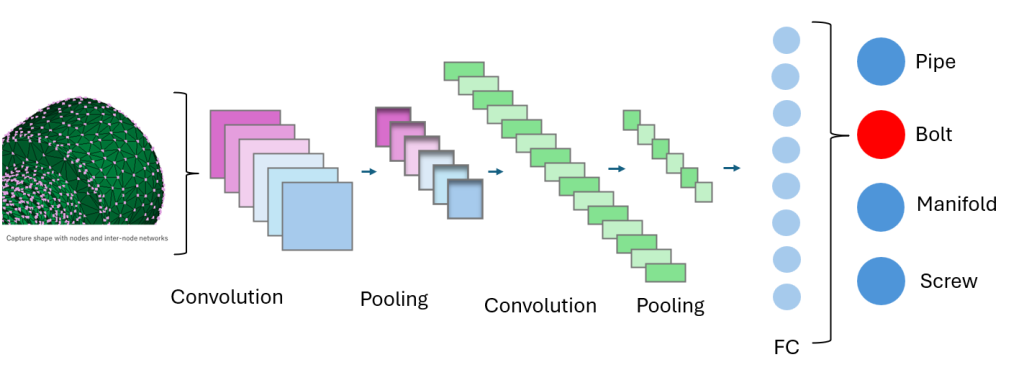

It uses 3D convolution technology that preserves the features of the shape as much as possible, so it is possible to classify either by focusing on one part of the shape or by looking over the entire shape.

For many years, simulations designed for CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and CAE (Computer-Aided Engineering) have been integral to the manufacturing and industrial sectors. Established industries often possess hundreds, if not thousands, of 3D data models accumulated over the years. Managing such a vast collection of designs is a complex and challenging task.

3D Shape Classification is essential for various industries, including manufacturing, healthcare, and virtual reality. By accurately identifying and categorizing 3D shapes, businesses can streamline their processes, improve product quality, and enhance user experiences.

Fortunately, AI has excelled in classification across various applications, especially after the discovery of convolutions method. Now, Astraea Software brings this expertise to 3D data with our advanced 3D Shape Classification technology.

key Advantages of 3D Classification Artificial Intelligence is Efficiency, Versatility and Scalability.

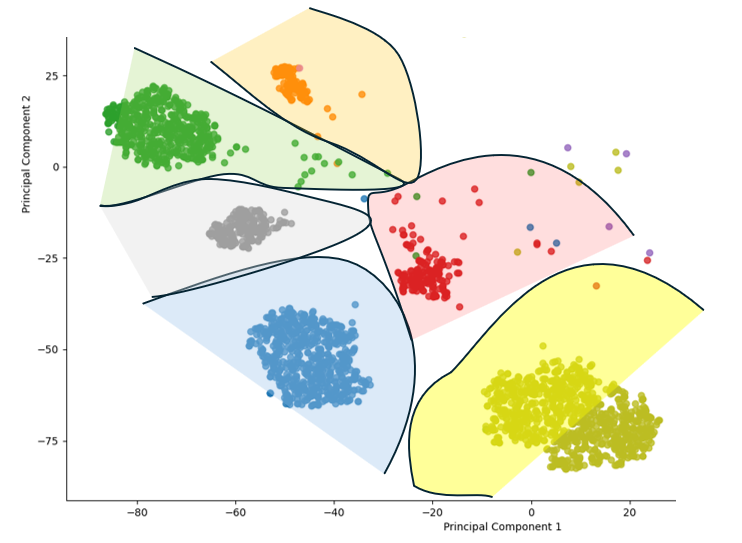

Our 3D Shape Classification system utilizes state-of-the-art convolutional neural networks (CNNs) and others architecture that compatible to analyze and classify a 3D object shape based on their geometric features. By processing features of 3D object either its a mesh or pointcloud, the AI Architecture can provide a accurate classifications based on classes that custom-designed.

In the realm of 3D classification, AI models typically employ discriminative models, which are a type of supervised learning. This means that the classes must be predefined before the training process begins. The features extracted from the 3D model shapes are based on the specific aspects that need to be classified. Consequently, not all classification models utilize the same features. Features that are important in one AI model may not hold the same importance in another.

For instance, in a model designed to classify bolts, the shape of the bolt head might be a critical feature. However, in a model aimed at classifying pipes, the diameter and curvature might be more significant. This variability underscores the importance of tailoring feature extraction to the specific classification task at hand. By doing so, the AI model can achieve higher accuracy and relevance in its classifications.

In addition, 3D shape classification can be used not only for classification but also for other tasks.

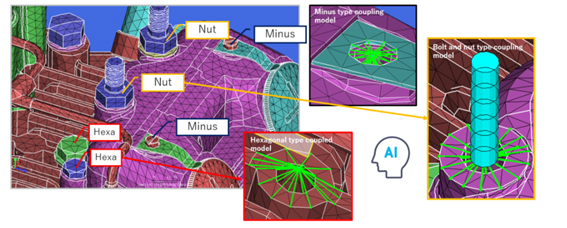

When creating a mesh model for CAE simulation analysis from an assembly CAD model such as an engine, the CAE coupling model according to the classified bolt type can be automatically inserted, and the time required to create a series of mesh models can be significantly reduced.

Hundreds of bolts were used in the assembly model of the engine, and it took a lot of time to create the CAE coupling model.

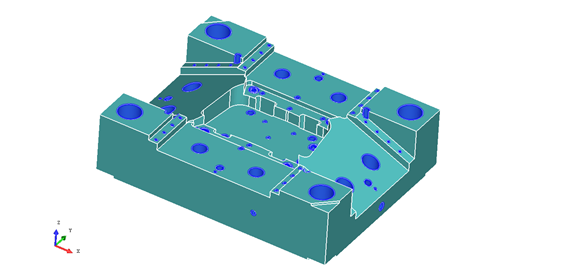

In addition, when calculating the cutter path for NC lathes for injection molding dies and forging dies, the bolt hole shape can be identified from the mold model and automatically deleted from the overall shape.

This is because the bolt holes are created after NC machining and must be removed from the overall shape before calculating the cutter path.